Common rubber mixing cooling process in rubber enterprises

2021-01-15(2807)Views

Film cooler is often used for film cooling of tablet press in internal mixing workshop. After plasticizing or mixing, the rubber material is pressed into a film; this device can take in the film with a higher temperature, joint, compact, cut the film longitudinally and horizontally, print, cool the release agent, lift the hanger, air-cooled and reduce the temperature.

Fold into piles. The system is composed of a host computer and an electric control system. The host is further divided into a receiving device, a cooling device, a lifting device, a glue hanging device, an upper swing device, a lower swing device, a railing, a platform, and a supporting frame. The electric control system consists of a main box, and an emergency control device is installed at the key part of the equipment, which is convenient for workers to operate and has a spacious vision.

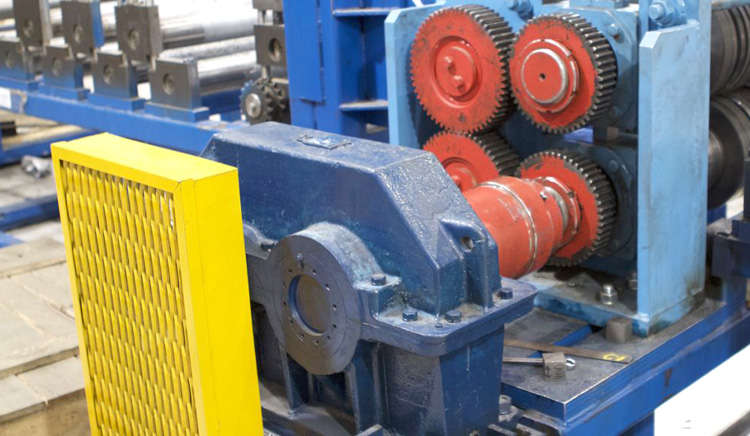

The rubber from the extruder in the mixing workshop first enters the front take-up device of the film cooler. The front of the take-up and conveying device is composed of a high-temperature conveyor belt, and the rear is a power roller system. The conveyor belt is without joints. Heat and corrosion resistant nitrile belt. The device has a correction device and an automatic tensioning device.

The rubber material passes through the pinch roller and enters the isolation coolant water tank after the front pick-up. The main and auxiliary water tanks are divided into single-layer structure. The film enters the immersion tank, soaks the isolating agent in the tank and gets preliminary cooling. The immersion tank is equipped with a cooling circulation device and isolating agent stirring pump. Then enter the lifting and hanging glue device, through the G120 inverter to ensure that it matches the line speed of the upstream frame.

?After that, the film soaked in release agent is clamped and lifted by the clamping lifting conveyor belt and then entered into the air-cooled device by the plastic module conveyor belt. The lifting device has the function of automatic film hanging. The glue conveying device is added to the lifting position to adjust the lifting angle of the film. (Adapt to soft and hard rubber), so that the entrance of the hanging piece is smooth without squeezing glue.

The film fed by the lifting device can automatically enter the glue-hanging rods to prevent glue blocking, so as to ensure reliable automatic glue-hanging, avoid the danger of manual glue-hanging, and reduce the difficulty of operation. At the same time, it is equipped with a detection device, which automatically alarms and stops working when the glue is blocked. PLC control makes the hanging glue length consistent and neat, with manual and automatic functions.

After the cooled rubber material is detected, the automatic rubber pick-up waiting position is detected by the photoelectric switch, the lifting cylinder of the automatic rubber-picking device drops from the rising limit position to the waiting position and waits for the glue to be picked. When the pick-up photoelectric switch detects the position of the pick-up film automatically. The lifting cylinder of the automatic glue picking device changes from the waiting position to the grabbing position.

At this time, the grabbing cylinder shrinks to grab the film. After the grabbing cylinder shrinks to the upper limit magnetic switch, the elevator cylinder rises to the rising limit position, and the magnetic switch is electrically induced , The translation cylinder moves to the limit position of the translation cylinder. After the magnetic switch is electrically induced, the piston rod of the roller cylinder extends to press the film. After the magnetic switch is electrically induced, the conveying motor and the swing film motor are started, and the conveyor belt runs and the film enters the conveyor belt. After rolling, close to the switch's electrical back. The piston rod of the roller cylinder retracts, and the translation cylinder retracts. The width of the swing rubber is processed by PLC on the basis of the setting, and the width of each layer decreases.

At the same time, each swing of 2 swing servos controls the receiving tray to drop a certain height to ensure that the rubber is evenly and neatly placed on the tray. The automatic glue picking device returns to the initial position and waits for the start of the next program.

Finally, the lifting servo will drop the pallet to the conveying position, and the conveying roller will automatically send the pallet with the material into the glue picking position and wait for the worker to transport the glue away. At the same time, the system automatically controls the empty disc conveying roller table and related cylinders to complete the empty disc conveying, waiting for the next disc of rubber material.

Latest News

-

Precision Rubber Preformer Rubber Filter

The computer version of the precision pre-forming machine is...

-

4 points of attention when rubber injection molding machine extruder

People should not be in front of the mold before the plastic...

-

Kesheng rubber molding machine: advantages of rubber injection molding machine

It simplifies the process of producing rubber molded product...

-

Functional advantages of liquid silicone feeder

With the needs of the ever-changing industrial development, ...

0769-38955228

Hotline:0769-38955228

Phone:13826937784

Fax:0769-38955226

Email:webmaster@szksma.com

Address:Dalai Management District, Huangjiang Town, Dongguan City, Guangdong Province

13826937784

13826937784